How to ensure the dimensional accuracy and shape accuracy of the product during the cutting process of color cutting vinyl? Are advanced measurement and control systems used?

HANKER's production base is equipped with domestic and even internationally advanced cutting equipment, which integrates high-precision servo motors and laser positioning systems to achieve micron-level precision cutting. The use of servo motors ensures that the cutting head moves accurately on the X and Y axes, and can maintain extremely high positioning accuracy even at high-speed cutting. The laser positioning system uses non-contact measurement to accurately identify the edge of the material, further improving the accuracy of cutting. The built-in automatic calibration function of the equipment regularly adjusts the mechanical parameters to compensate for minor deviations in long-term use, ensuring long-term stable cutting accuracy.

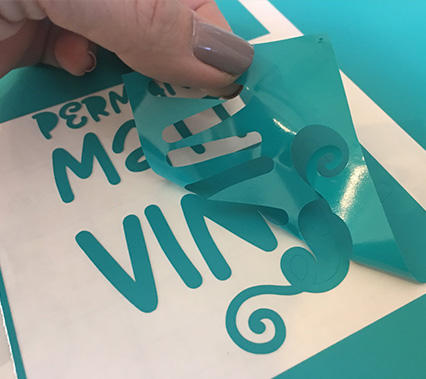

In addition to the hardware advantages, HANKER also uses advanced cutting software, which has built-in complex algorithms that can automatically optimize the cutting path according to the design file, reduce material waste, and effectively avoid deformation problems during the cutting process. The software supports multiple file formats, such as AI, CDR, PDF, etc., with strong compatibility, which facilitates seamless connection between designers and customers. More importantly, the software has intelligent recognition function, which can automatically identify the contour features of the graphics, adjust the cutting speed and pressure to adapt to the cutting needs of different areas, thereby ensuring accuracy while optimizing cutting efficiency.

In order to ensure the size and shape accuracy of each batch of products, HANKER sets up multiple quality inspection points on the production line, and uses high-precision optical measuring instruments such as 3D scanners and laser rangefinders to inspect 100% of the cut products. These instruments can generate high-precision 3D data models, which are compared with the original design files, and any minor deviations can be discovered and corrected in time. In addition, HANKER has established a strict quality management system, following ISO 9001 standards, monitoring the entire production process, from raw materials entering the warehouse to finished products leaving the warehouse, and each process has detailed quality records to ensure product quality traceability.

HANKER's color cutting vinyl material itself has also been specially designed to enhance its stability and accuracy during the cutting process. For example, its dimensional stability is good, and it can maintain its shape even in an environment with large temperature fluctuations, which is particularly important for large-scale installation projects such as outdoor billboards. The material provides two options of glossy and matte, as well as up to 55 colors to meet the aesthetic needs of different application scenarios. It is particularly worth mentioning that the material uses a solvent-based transparent permanent acrylic adhesive, which is suitable for most substrates. It is not only firmly adhered, but also not easy to peel off at the cutting edge, further ensuring the overall beauty and durability of the finished product.

While pursuing technological advancement, HANKER also actively responds to the call for sustainable development. The R&D center continues to explore the application of environmentally friendly materials, as well as production processes that improve material utilization and reduce waste in the production process. For example, by optimizing the cutting path algorithm, the generation of scraps is reduced; production in a dust-free workshop avoids dust pollution and ensures the cleanliness of the material cutting surface, which also creates favorable conditions for subsequent processing and application.

English

English 简体中文

简体中文